Techflow Enterprises Pvt Ltd is competently one of the most trusted and biggest suppliers of products like Pulse Jet Bag filter, Dust Recovery System, Bag House, Air Pollution Control Device, De-Dusting System, Furnace Fume Extraction System, Electrostatic Precipitator, ESP, Bag Filter, Silo Vent Filter, Online Cleaning Bag Filter, Cassette Type Filter, Air Pollution Control Equipment, Centrifugal Fans & Blowers, Flue Gas Emission Control System, Pneumatic Conveying System, Pulse Jet Dust Collector, Fabric Filter, Offline Cleaning Bag Filter, Reverse Air Cleaned Bag Filter, Welding Fume Extraction System to different industries domestically and globally.

We, at Techflow Enterprises Pvt Ltd, have been delvering necessary instruments to many industries like Cement, Kiln Exhaust, Mining and Minerals, Particle Board Manufacturing, Air Pollution Control Systems, Coal Handling, Foundry & Steel, Boilers Flue Gas, Solid Drying, Glass, Wood-Working & Laminates, Hot Gases and Fumes, and many more industries.

Discover more| Bag Filter For Boiler |

|---|

Boilers are fundamentally used to generate the steam for Power Plants, Chemical Plants, Sugar Mills, Process Houses, and more. In order to generate steam, these Boilers use Renewable Energy, Solid Fuels, LPG, Electricity, Gas, and Oil. Out of the listed fuels, solid fuels are the cheapest and the most used source though being the most polluting. Aiming to control this solid fuel emission, TECHNOFLOW produces and supplies the greatly efficient pollution control system. These systems go by many names globally, for instance, Pulse jet bag filter, De-dusting system, bag filter for boiler, ESP for boiler, Pulse jet bag filter, Bag house, and Bag Filter. There are various types of pollution control equipment or bag filter in order to control the emission from different types of solid fuels like Bag Filter for bagasse fired, bag filter for wood fired boilers, waste incineration boiler for waste to energy plants, Bag filter for Coal fired boiler, Bag Filter for food and agriculture waste fired boilers. TECHFLOW proudly supplies all of them as required. |

Techflow is a trusted manufacturer and supplier of Bag Filter type air pollution control system based in Ahmedabad, Gujarat. With exports all around the world, Techflow's customer centric approach and providing the best solution for controlling air pollution in industries has made it a reliable associate for many industry segments making it a preferred partner for catering to their needs for best quality bag filter. |

The major plants where the air pollution control systems for boilers are usually supplied to are – Cement Plants, Dairy, Steel Plants, Paper, Power Plants, Chemical Plants, Sugar Mills, Process Houses, and Pharmaceuticals. |

Based on the fuel and requirement of outlet emission, TECHFLOW Designs and supplies Pollution Control System and Pulse Jet Bag Filter for boilers. Describe below are the two major types of TECHFLOW-used pulse jet bag filters control pollution of boiler. |

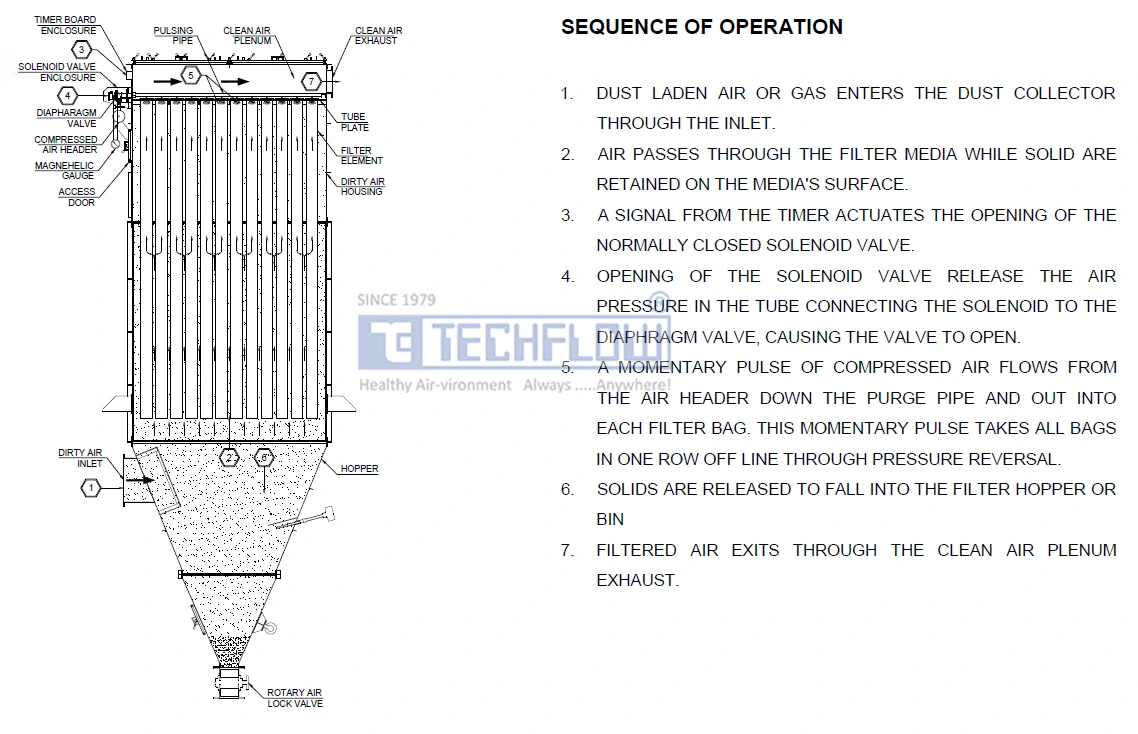

1. Online Cleaned Pulse Jet Bag Filter

Where the heavier particles drop out of the airstream, the dust laden air enters the hopper. The particles that are lighter are entrapped in the air which as a result rise into the filter bags. The passing of air through the filter bags results in the dust particles being collected on the outside surface of the filter bags as the cleaned air gets exhausted out via the collector. The jets of compressed high-pressure air, at precise intervals, passed through the venturis thru pulse and blow pipes. This includes a briefly reversing strong flow of secondary air through the bags. This leads to the production of an internal shock wave that causes the bag to pressurise and flex outwards as the shock travels down the length of the bag. The process lets the dislodgement of the dust of the reversed airflow on the exterior of the bag which then falls down into a collection hopper. Airflow through a row of bags if reversed through this process, but only for a brief second. Throughout the dust collector, this then results in a steady state of airflow. Via a Solid State timer, the Cleaning Operation is easily controlled and adjusted. The ideal regulation of the timer is permitted and controlled by a differential pressure gauge. In order to minimise the compressed air consumption in the process, the pulse intervals and durations can be accurately and simply adjusted at the timer.

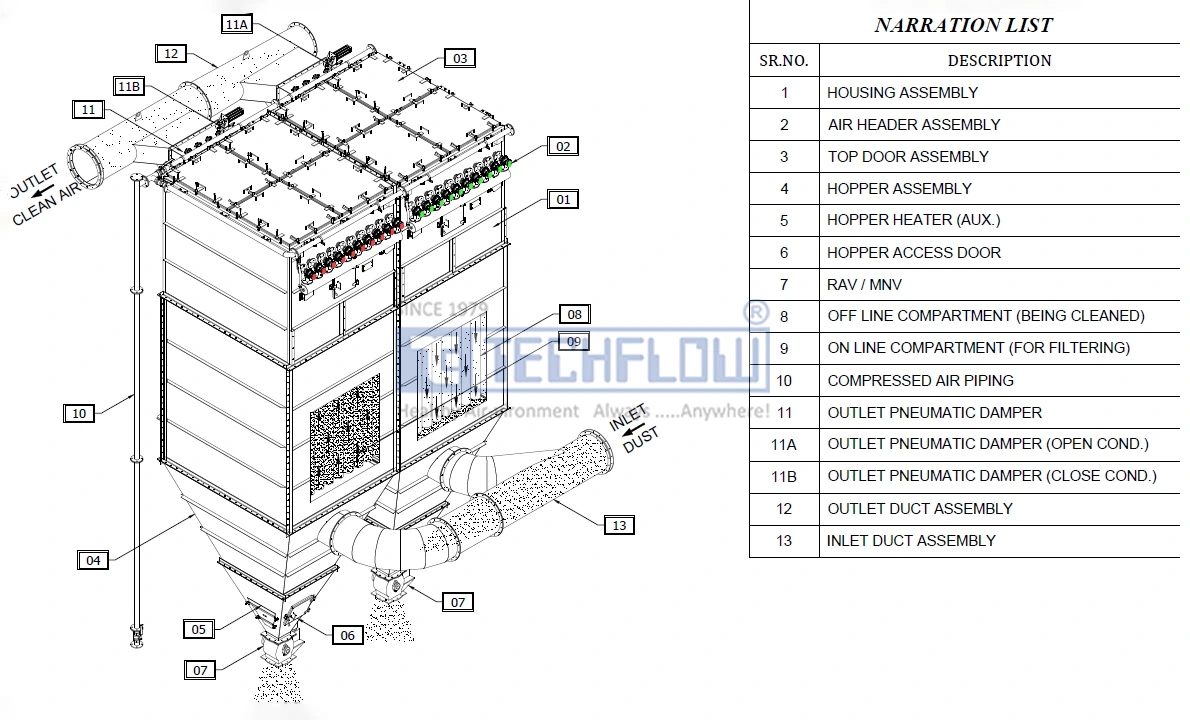

2. Off line Cleaned Pulse Jet Bag Filter

Compartmentalization of Pulse-Jet baghouses is also possible. In this Scenario, the flow of the dirty air into the compartments is stopped by the Isolation/Poppet valves located in the clean air plenum. There is an option to equip each of the compartments with either a single pulse valve that provides the group of bags with compressed air, or have the direct pulsing air blown into the blow pipes that are above the bag rows in the compartment via separate pulsing valves. The air flow through the compartment is stopped during the cleaning cycle as the isolation damper closes. For the cleaning process, a burst of air is supplied into the bags through the opening of the pulse valve for about 0.2 seconds. During the pulsing process, the compartment stays offline. The time period for that, however, can be longer or shorter as required. The compartment is brought back on stream upon the automatic reopening of the Isolation/Poppet. Through the process called Off-line Cleaning, until and unless all the bags in the baghouse have been cleaned, the alternate compartments are successively cleaned. While the bag house continuously achieves very low emission levels, It allows very thorough bag cleaning as it is frequently used on fabric filters installed on low bulk density product/dust.